Page 64 - MASALA Magazine Vol.15 Issue 3 | February - March 2024

P. 64

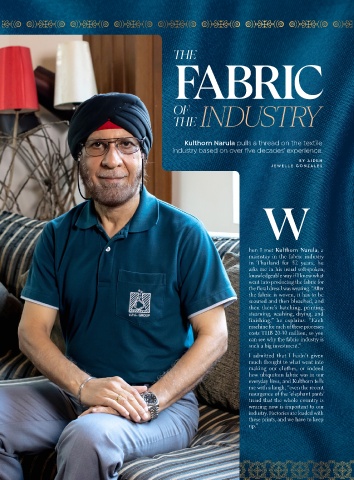

Kulthorn Narula pulls a thread on the textile

industry based on over five decades’ experience.

B Y AIDEN

JE WELLE GONZ ALE S

hen I met Kulthorn Narula, a

mainstay in the fabric industry

in Thailand for 52 years, he

asks me in his usual soft-spoken,

knowledgeable way if I knew what

went into producing the fabric for

the floral dress I was wearing. “After

the fabric is woven, it has to be

scoured and then bleached, and

then there’s batching, printing,

steaming, washing, drying, and

finishing,” he explains. “Each

machine for each of these processes

costs THB 20-30 million, so you

can see why the fabric industry is

such a big investment.”

I admitted that I hadn’t given

much thought to what went into

making our clothes, or indeed

how ubiquitous fabric was in our

everyday lives, and Kulthorn tells

me with a laugh, “even the recent

resurgence of the ‘elephant pants’

trend that the whole country is

wearing now is important to our

industry. Factories are loaded with

these prints, and we have to keep

up.”